Flexible feeding of parts becomes increasingly important

The increasing demand for flexibility in production to assemble small batches in multiple versions in the factories of the future and with Industry 4.0 requires solutions for the flexible supply of parts.

Transporting small parts and presenting them in the right way for the next work step. This requires a system with different components and possibilities - especially if different parts must pass through it.

To make the whole process, including the changing of parts, run smoothly, Hupico offers FlexFactory's patented AnyFeeder solutions.

Double guarantee

On the one hand, we guarantee an extremely high level of process stability: the reliability of these systems prevents downtimes and keeps your production lines running. On the other hand, flexible feeding systems keep pace with the highly variable and short product life cycles found in every industry.

Our systems can remain in your production line permanently, regardless of the products and components: whether it is a complete model change or changes to individual components during ongoing production.

All specifications in a convenient overview

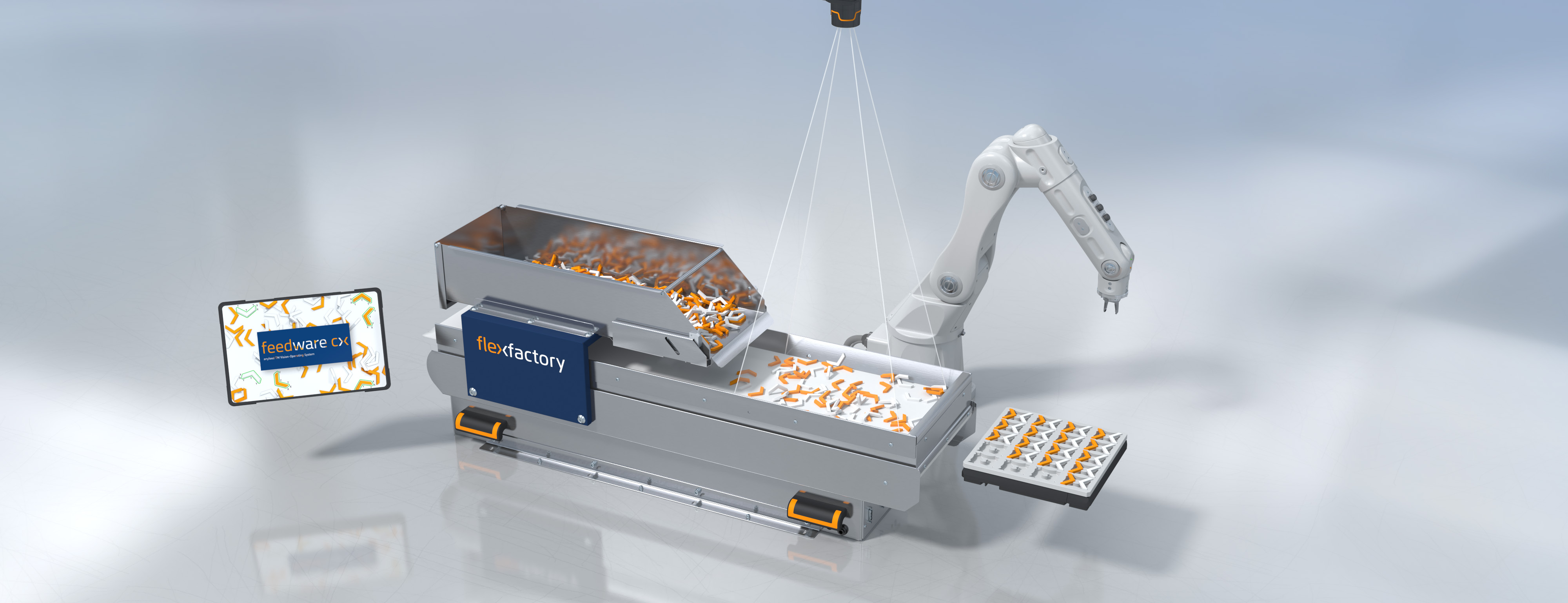

The Anyfeed flexfeeder is available in 6 sizes and aims to manipulate the products from bulk in such a way that they can be picked up by a combination of vision and a robot and arranged for further processing (assembly / inspection / packaging, ...).

The three new feeders - Coming in June 2022

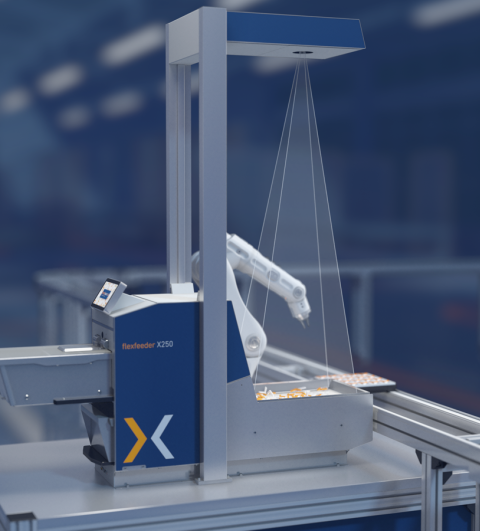

The three newly developed feeders of the flexfeeder product family mark the current state of flexible feeding technology. With fully integrated camera and toplight tower, the flexfeeder systems drastically reduce commissioning times compared to all previous systems due to their ready-to-use wired system. The integrated touch screen simplifies parameterization and operation and provides valuable data on system performance during ongoing production.

The fully integrated camera and control system with included touch screen, based on the latest feedware X software, also makes every flexfeeder the ideal partner for collaborative robots.

Our customers master the technology we deliver completely independently. Included in the scope of delivery of each system are drivers for almost every common industrial robot.